A sophisticated industrial wastewater pretreatment design was required for the Bel Brands USA cheese processing facility in Brookings. Overall, the system reduces the strength of the wastewater to minimize the impacts to the Brookings Wastewater Treatment Facility. Its primary treatment method is Dissolved Air Flotation (DAF) followed by an Upflow Anaerobic Sludge Blanket (UASB) digestion process. The facility also includes flow equalization and an odor control system. On the front end, a flow equalization (EQ) tank allows the facility to avoid slug loads and spread the loading out through the day. The DAF process efficiently reduces solids loadings including fats, oils, and grease to protect the operation of the UASB process. The UASB process decreases the organic loading concentration to meet the industrial permit for discharge into the Brookings wastewater treatment system. Due to the close proximity of these facilities to Brookings, odor control facilities were included to draw air from the DAF and EQ tank and treat it in a fixed film (woodchip) bioreactor bed to tie up odor-causing compounds before releasing it into the air. The industrial pretreatment facility was designed to minimize energy needs while meeting the treatment goals. The UASB give off biogas—mostly methane like in natural gas—that is available in sufficient quantities to fire a boiler, providing heat back to the system to maintain temperatures. The warmer treated wastewater and cooler raw wastewater are run through a heat exchanger to preheat the influent water and minimize the heat required to maintain temperatures in the reactor. This process offers significant energy savings and reflects the design intent of minimizing energy consumption while meeting the treatment goals. The project was constructed in a time frame to coordinate with the start up of the cheese processing facility, and was completed within the budget for the project. This project was unique in that the City of Brookings participated with Bel Brands to construct the pretreatment facility. Banner Associates worked close with both owners to identify both the major goals of the process as well ongoing needs throughout the design and construction of the facility.

Project Goal #1

Design a pretreatment facility that will meet the industrial pretreatment permit limits for the facility that fit within the budget for the project

Project Goal #2

Design a facility that can be constructed and put into operation to coincide with the start up of the cheese processing facility

Project Features

- Equalization Storage

- Dissolved Air Flotation (DAF)

- Upflow Anaerobic Sludge Blanket Process

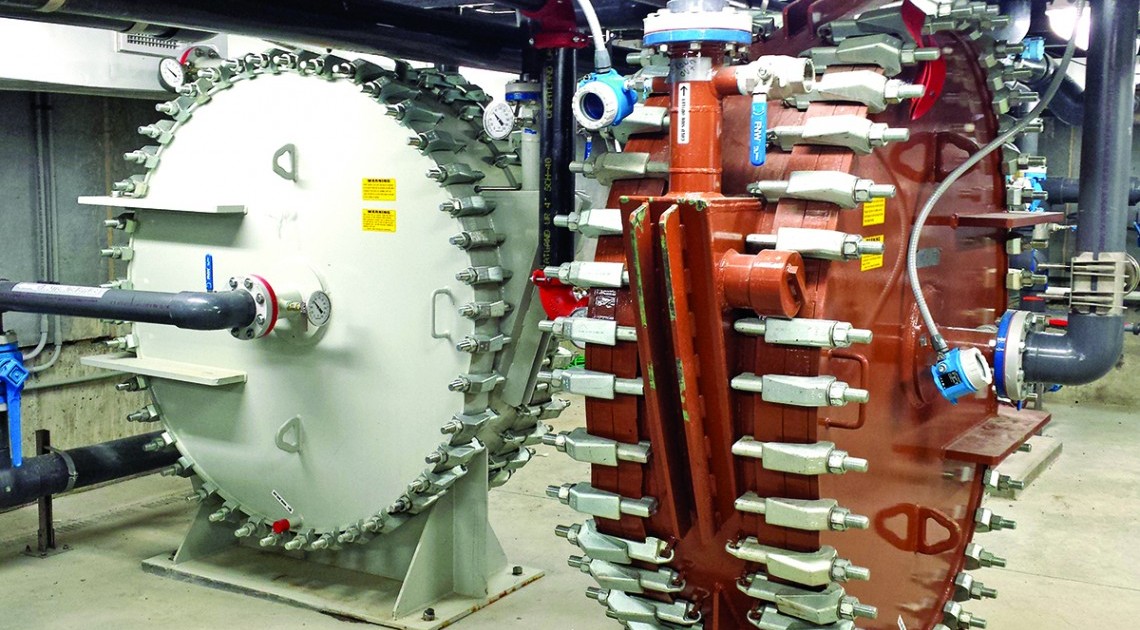

- Heat Exchanger

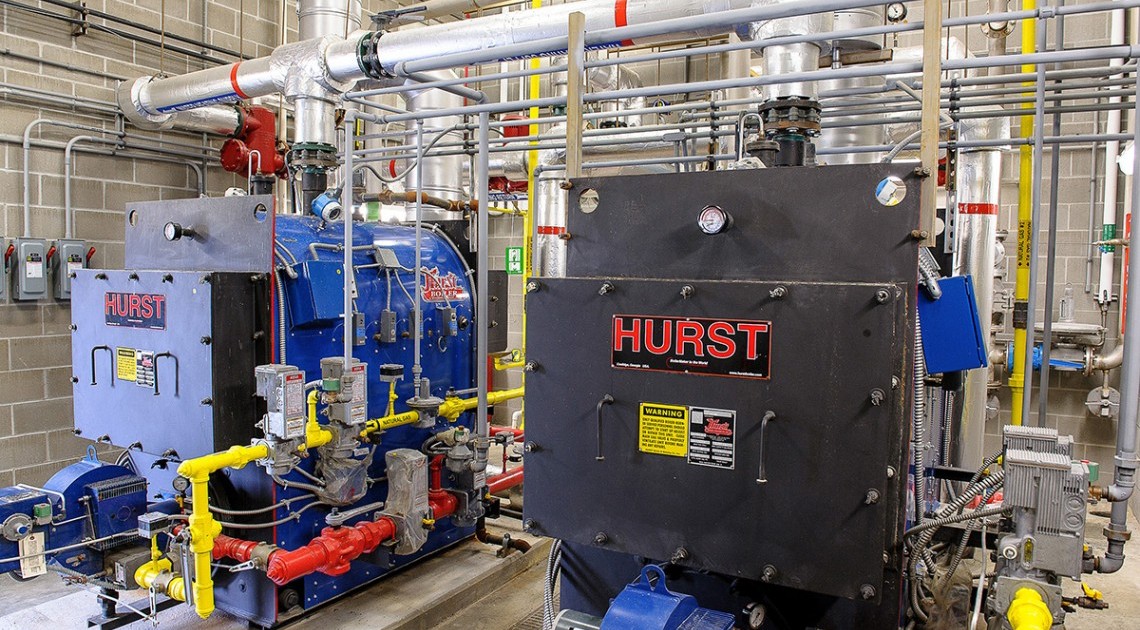

- Boiler System

Services Provided

- Facility Plan

- Topographic Survey

- Preliminary/Final Design

- Construction Documents

- Bidding Services

- Construction Contract Administration

- Construction Staking and Observation

- Operations and Maintenance (O&M) Manual