Tiny Homes, Big Options: New Housing with the Flandreau Santee Sioux Tribe

Neil Eichstadt | Nov 30, 2022

When exploring ways to expand housing options for their tribe, the Flandreau Santee Sioux Tribe came across Tiny Homes as a potential solution. With their small footprint and clever interior layouts, Tiny Homes bring many of the same amenities found in their larger counterparts in economic and efficient means. To ensure this new neighborhood offered the best living experience for residents, the Flandreau Santee Sioux Tribe turned to Banner for a number of engineering services; we were thrilled to take part in this project and help make this a great place to live!

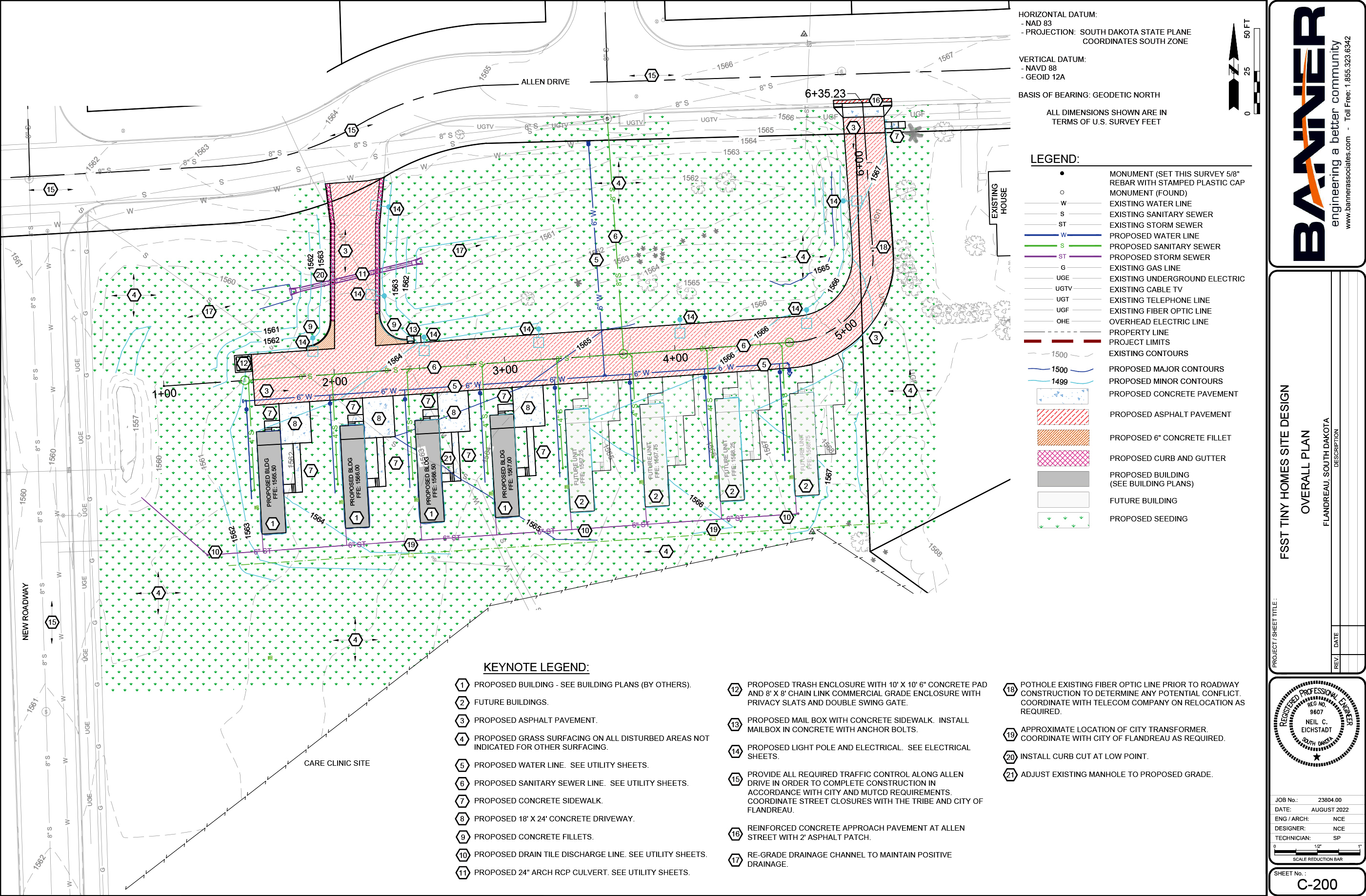

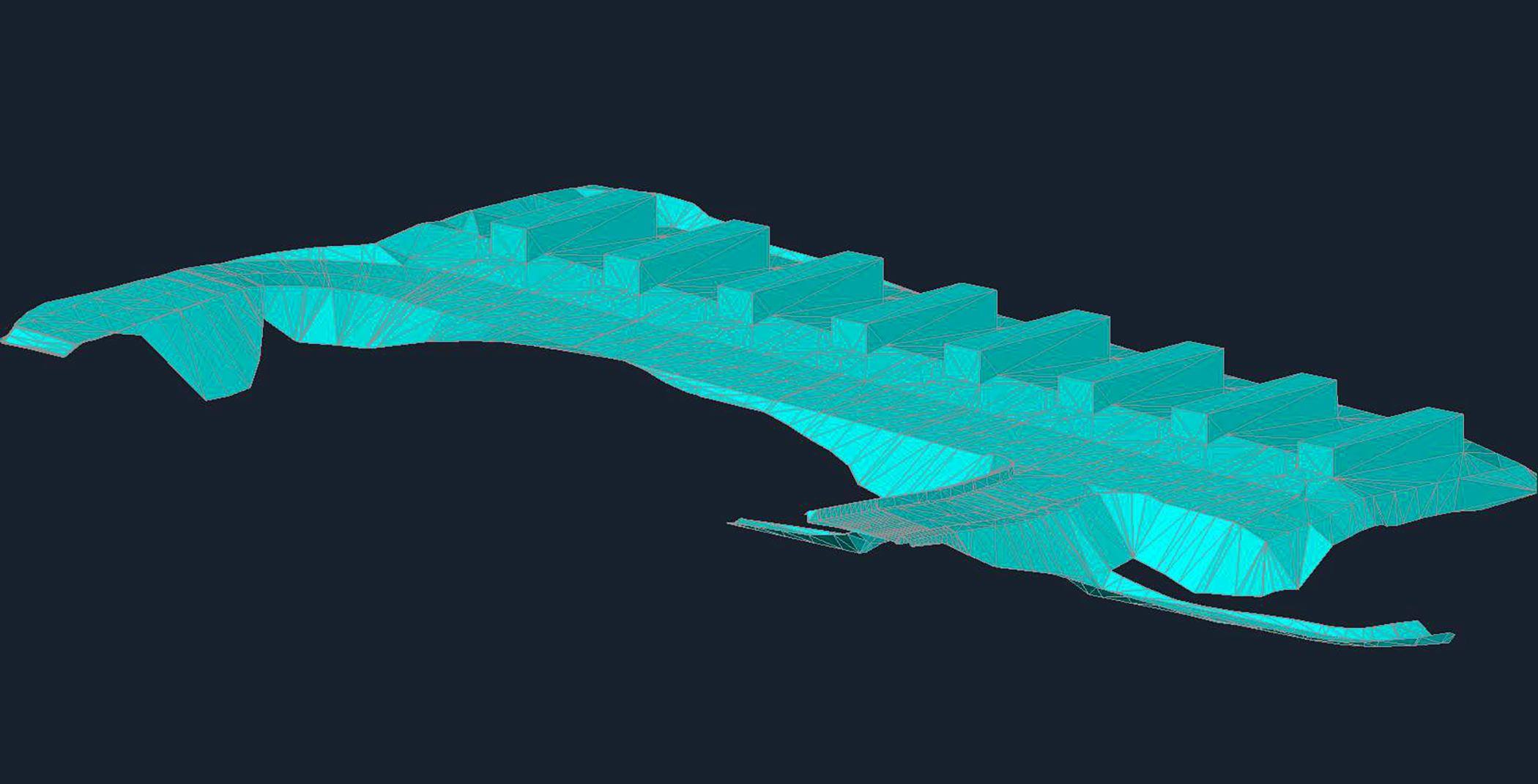

The strategy the Tribe decided to implement was to work with us to develop the proposed Tiny Homes site while also working with a Tiny Homes supplier to ship fully-constructed homes directly to the housing development site in Flandreau.

Once on site, the Tiny Homes were set into place using a crane. Each Tiny Home is set atop a concrete foundation with a crawl space. Outside, the rest of the housing development will have the same sorts of features we expect in a neighborhood: roadways, utilities, sidewalk, and other infrastructure to support the Tiny Homes.

Throughout the project, there were some key aspects considered and implemented for this development:

- Review Tiny Home building plans and determine the site infrastructure needs for each unit.

- Analyze the existing site and determine the appropriate placement of the Tiny Homes within the limits of the project to maximize the use of the site. It was also important to avoid too many units being “shoe-horned” which would detract from the quality of life for the tenants.

- Divide the project into phases to ensure proposed site can accommodate future phases.

- Lay out roadways and utilities with the Tiny Homes to ensure proper access while maximizing use of the required materials.

- Factor a major drainageway along the north side of the site into the placement and elevation of the homes to avoid potential issues in large storm events.

- Ensure optimal traffic flow in and out of the development and for the finished neighborhood.

- Optimize existing site topography and drainage away from homes with site grading.

- Evaluate other site aspects like street lighting, mail delivery, and trash collection.

Hydraulic Modeling: More Than a Pipe Dream

Jessica Weinkauf | Aug 31, 2022

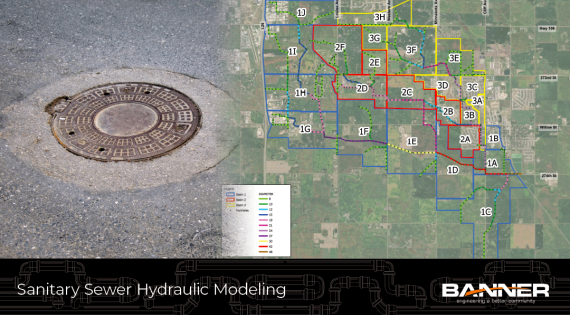

Welcoming more people, businesses, and/or industries to any given city often brings infrastructure challenges: what existing infrastructure can support the growth? What infrastructure will need to be replaced? Of course, these are just a few of the questions that come up when considering upgrades / expansions to infrastructure, and it can be difficult to know all the right questions to ask. Two growing South Dakota cities, Colton and Harrisburg, had unique challenges to address with their wastewater system infrastructure. To find the best route forward for each City’s individual needs and goals, Banner used Hydraulic Modeling.

Hydraulic Modeling is, in many ways, exactly what it sounds like. We use specialized software to create models of hydraulic systems to illustrate the complex effects of changing conditions on the sanitary sewer system. These hydraulic models display information on system components like pipes and pumps in multiple media forms like maps, tables, and graphs. Hydraulic modeling software allows us to study existing sewer systems, investigate proposed changes, and compare these findings against the projected system needs. For Colton, this meant looking at the impact of a growing residential footprint.

While planning a new residential development, the City of Colton wanted to determine if their system could handle the added wastewater, or if they needed to make a change. We gathered data and set to work on a hydraulic model to depict the impact of increased flows from the new development as the homes are filled over time. The model indicated the system needed some improvements and increased treatment capacity to support the full development. The City of Colton used this information to plan a phased approach with the developer to accommodate the sewer system improvements.

With even faster population growth on the horizon, the City of Harrisburg needed similar services. Known as the fastest growing city in South Dakota, Harrisburg faces challenges supporting that growth with their infrastructure. Adding a new area requires significant time investigating, evaluating, and planning options for expanding the sewer system. Adding multiple areas requires a strategy. Banner recently completed a long-range sewer system expansion study for the City of Harrisburg, detailing options to provide sewer service to 9,865 acres of future development land. Hydraulic modeling of the sewer system helped determine optimal and cost-effective pipe locations, sizes, and depths to provide sewer service for the area. From the model, we also:

- Established when existing sewer piping would reach capacity and require upsizing.

- Verified installation of large-diameter gravity sewer would allow the City to eliminate three sewer lift stations.

- Determined a sewer cross connection between basins was the most cost-effective alternative because it reduced downstream sewer pipe size requirements and demonstrated a portion of the existing trunk sewer could convey projected flows.

- Evaluated the ability to use dual, parallel sewers to phase installation and spread out the project cost.

Colton and Harrisburg are two cities among dozens we have helped with Hydraulic Modeling. From determining if / when upsizing and upgrades are necessary to the impacts of new development and industry on sewer systems, Banner uses sewer modeling to help our communities determine the best course of action for each individual situation. Ready to bring a positive change to your community? Contact us to get started—we look forward to Engineering A Better Community with you!

Get the Word Out: How Banner Helps You Communicate Your Project

Banner Associates, Inc. | Dec 09, 2021

Everyone knows good communication is foundational for a successful project. In most cases, it manifests as the team meeting regularly, discussing openly, and making sound decisions per the project plan. Project plans, however, sometimes overlook communication with audiences that may be critical to the project’s success. When it comes to communicating with local decision makers, stakeholders, the public, and more, your project needs a communication plan. Banner’s Strategic Communications team is here to help!

Each community—and the audiences in them—has different needs. Local decision makers may want a full presentation, or they may want a one-page flier. Stakeholders might need an in-person meeting to discuss details and ask questions, or they might want a packet. Members of the public could want town hall meetings, mailers, or social media updates. Your project’s communication plan may need one of these, but it might need all of these. We work with you and your community to determine which communication paths best meet the needs of each audience, and then we help put together effective content.

Of course, we brought examples. We put together this data sheet for a bank stabilization project in Yankton, SD to help the project team address common questions from the public. When the South Dakota Department of Transportation needed the Winter Highway Maintenance Plan updated, we edited the verbiage and pumped up the graphics, upholding SDDOT brand standards throughout. The sign posted outside the new housing development? We do that, too. Our social media accounts have regular updates and milestones for projects big and small for communities to share with their followers. We also help communities with digital assets (e.g. logos) that they can use for their own social media, website, print publications, and more.

With Banner, you get more than an engineering firm. Our dedicated Strategic Communications specialists can help throughout your project with polished, informative content for every audience. Get in touch with us today to get started!

Thanks for reading!

Level Up: How Surveying Helps Communities Grow

Banner Associates, Inc. | May 06, 2021

Everything ages. As equipment and facilities reach the limits of their useful life, some companies will opt to do more than replace and update: they use it as an opportunity to expand. With the right information on the inner workings of the building, an expansion seems simple enough. Like everything aging, however, the earth is always shifting, and even subtle changes can have huge impacts on any expansion project. To make sure we have a complete picture of the conditions, we use various land surveying techniques to gather data on the land and any changes that have occurred. This data factors into design and construction, ensuring the new (or reconstructed) sections match the existing facility. One of these techniques is line leveling.

Line Leveling is a simple but essential part of surveying and engineering. It starts with finding fixed metal anchors in the earth known as National Geodetic Survey (NGS) monuments. Monuments are cataloged in the NGS database as a single point for all past, present, and future survey data. When surveying, we use a level and grading rod to create a level loop, which is a series of elevations collected by leap-frogging from point to point until we return to the original spot, collecting data along the way. From there, we “check in” to determine if the level loop data is within tolerance and run additional calculations to adjust for any errors that occurred throughout the process. The result is accurate elevation data for the surveyed area, which is critical for design and construction.

As an example, we are working with WEB Water on a project to expand a facility. This particular facility presents unique challenges, as it has plan sets spanning across multiple decades which use varying data points. In Surveying, these data points are known individually as Vertical Datum: they serve as a point of zero elevation that we use to determine the elevation of other points in the surveyed area. Since the earth is always moving and undulating, a vertical datum can change over time. Beyond that, each plan set through the years used a different vertical datum.

We set to work, obtaining accurate elevations of important features like tanks and finished floors using a new vertical datum. From there, the design team will be able to compare elevation data from the previous plans with current elevation data, designing an expansion that can seamlessly incorporate with the existing buildings.

Project Spotlight: Lewis & Clark Regional Water System

Banner Associates, Inc. | Jan 20, 2021

Iowa Segment 3: Water for the Iowa members of Lewis & Clark

Iowa Segment 3: Water for the Iowa members of Lewis & Clark

The Lewis & Clark Regional Water System Iowa Treated Water Pipeline – Segment 3 is the last Segment of pipe construction that needs to be completed to allow water to be delivered to the Iowa members of Lewis & Clark (Sioux Center, Hull and Sheldon). Iowa Segment 3 is just 1 of 3 projects being constructed by the same Contractor between Beresford SD and Sioux Center IA. Total length of all three projects is 33.45 miles to install a 24-inch diameter pipe to transmit treated drinking water. The Iowa 3 project itself is 12.59 miles. When finished the pipeline will ultimately deliver 3.75 million gallons of water per day to the Iowa members.

Top Left: Assembling a joint of the 24-inch diameter bore pipe prior to welding. In order to protect the pipes internal lining during the welding process a unique coupling was utilized to protect the girth weld from corrosion. Bottom Left: This pull head will be welded to the 24-inch diameter bore pipe to allow connection of a drill stem for pulling the pipe under the Big Sioux River.

The Segment 12 project started at Beresford, SD, and consisted of 9.67 miles of 24-inch diameter PVC pipe. The Iowa Segment 2 project started at Sioux Center and went west and is 11.19 miles of 24-inch diameter PVC pipe. The pipe pressures are higher at the Big Sioux River valley, requiring the Iowa Segment 3 project to be either ductile iron pipe or steel pipe. The contractor chose to use a ductile iron pipe for most all of Iowa Segment 3 and utilized a welded steel pipe to cross under the Big Sioux River.

The Big Sioux River defines the boundary between South Dakota and Iowa and flows past the communities of Sioux Falls, and Hudson, SD and Hawarden, IA. It also collects the Rock River which flows from Luverne, MN.

Above: This is the drill rig/bore machine located on the Iowa side of the Big Sioux River. In the lower left corner of photo you can see the drill stem as it enters the ground. This drill stem has been extended under the Big Sioux River and into South Dakota. The bore machine via the drill stem will pull the 24-inch diameter pipe and centering it under the Big Sioux River and positioning it for a connection to 24-inch ductile iron pipe.

Top: Banner Associates Sr. Project Manager Scott Vander Meulen and a representative from the contractor review the directional drilling pulling head after it has been welded on the 24-inch diameter pipe. Protective coatings will be applied to the welded joint before the pipe gets pulled under the Big Sioux River. Scott has been involved in the planning, design and project management of this Segment of L&C for several years. Bottom: The contractor is moving the 1700 foot long steel pipe into position so that it can be connected to the drill stem.

In order to serve the L&C members of Hull, Sheldon and Sioux Center, IA, a pipe had to be constructed across or “under” the Big Sioux River. To install the pipe across the Big Sioux River the Contractor utilized a construction method known as Horizontal Directional Drilling or HDD. A pipe stem is drilled or advanced under the river from the Iowa side and once it emerges on the South Dakota side a larger reamer (drill bit) is attached to the stem and pulled back so that the bore hole is reamed to a larger diameter bore hole. Eventually the hole is reamed to a 36-inch diameter and large enough to allow the 24-inch water pipe to be pulled through the bore hole via the drill stem which is attached to the boring machine on the Iowa side.

The Lewis and Clark Regional Water System, a non-profit corporation composed of numerous municipalities and rural water systems, is constructing a water supply pipeline and associated well field, pump stations, treatment plant, and storage reservoirs throughout southeastern South Dakota, southwestern Minnesota, and northwestern Iowa. The completed pipeline system would be approximately 310 miles long, and will provide a high-quality reliable domestic water supply to residents of 14 counties in southeastern South Dakota, southwestern Minnesota, and northwestern Iowa.